DESCRIPTION OF PHASES MANAGED BY CLUSTRIA:

After an initial phase defining the product, during which its components and functional requirements are exposed, an industrial repartition takes place and parts are distributed amongst partners. The first phase, referred to as “plateau”, determines the interfaces between different work packages and the manufacturing schedule.

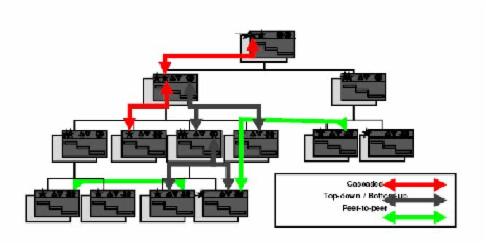

A contractual baseline for the product is established between the principal and the subcontractors, which is the birth of a functioning cluster.

At this point, the conception phase can begin at each of the risk-sharing partners.

1) Specification phase :

Driven by the programs, a phase where the different stakeholders take into account a modification and the specifications allowing to establish which part of the product (functional point) and the extent (aircraft, standard or variant) the change is applied. The modification is described in terms of costs, planning and technical requirements. Once all parties accept the modification, it is then “SPECIFIED” and job sheets are then sent to all involved.

2) Design phase :

Driven by the design office, an application of the previous agreed upon specification. An optimization called “modification stacking” allows the creation of one of more work sheets to develop the technical solution(s) needed to complete the modification. It initiates the design tool. This phase is completed once all the technical solutions generated by the modification have transmitted.

3) Planning phase :

Driven by manufactoring engineer or purchasing, a phase that integrates the modifications into the production process. It can begin as soon as the modifications are accepted (concurrent engineering). This phase also includes a set of processes to manage risk.

4) Manufacturing phase :

Driven by control and coordination, it allows comparisons between a models and finished products. At any time, it is possible to control the status of changes in terms of design and manufacturing. A technical drawing for a particular section is available to see the plans and/or models that represent retrofit solutions or solutions by series.

5)Delivery phase :

The delivery of the product sets the configuration in terms of actions of conception and fabrication. A report of all the phases is raised to establish the differences between the configuration and the finished product. A completion phase is then started with the client on site, allowing the differences to be settled.

6) Maintenance phase :

Driven by support services, this phase takes into account service bulletins and their compliance with airlines, but also follows modifications to maintenance technical documentation as well as policies related to the replacement of used parts.

7) Certification phase :

This phase allows the management of the configuration’s entire certification documentation. It operates alongside the previous phases.

DESCRIPTION OF PROFILES MANAGED BY CLUSTRIA:

CLUSTRIA has a set of processes covering the different phases and based on various profiles. Business-oriented ergonomics allows each user to accurately track all assigned tasks.

These profiles allow the management of all tasks linked to a product work package. A user and add several profiles for one or more work packages.

Program Manager

Market Manager

Design Manager

stress Manager

Certification Manager

Configuration Manager

Designer

Work Package Manager

Model Integrator

Tasks Manager

Coordination Manager

Quality Manager

Controller

Support Manager

Technical Publications Support Manager

Contract Manager

Marketing Manager

Administrator

A work package administrator manages the designation and subscription of users at the time of their enrollment.